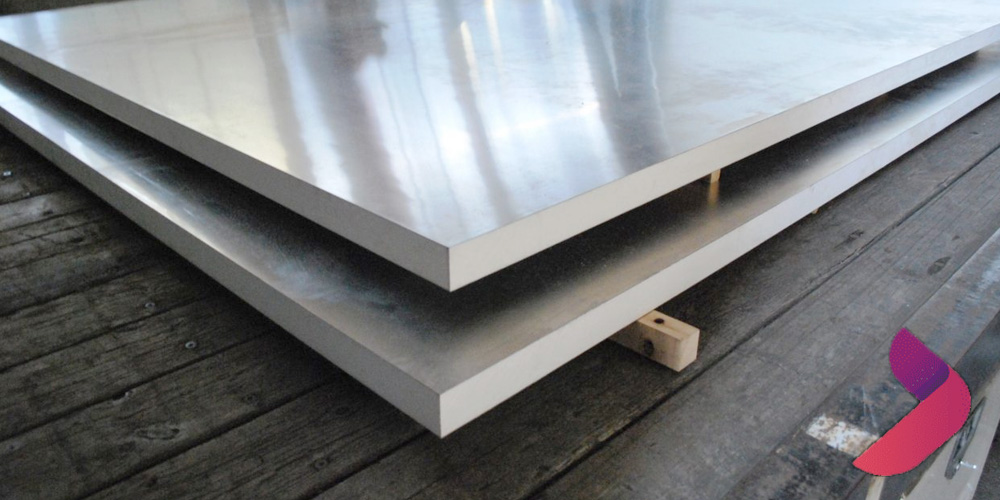

Lint Steels is one of the leading industries in the market for MP35N Sheet . Best raw materials are used for the production, which are tested and verified at every stage. We procure plates in different sizes, taking into consideration the specifications of client requests.

What are the useful properties of MP35N sheets and plates?

What are the features of MP35N sheets and plates?

The MP35N sheets have the unique combination of properties that are beneficial in many industries. They have the rare ability to be simultaneously sturdy, tough and pliable. Their erosion resistance is excellent. The MP35N plates are strong and malleable. The plates do not possess the property of embrittlement. They are strong and sturdy in their applications. They have fabulous machinability. The sheets are immune to stress corrosion. They also have high strengthened capacity to endure pressures. They show disparate performance in shipbuilding components. They are also used in the petrochemical and chemical industries worldwide. The plate has great use in medical implants.

Applications of MP35N sheets and plates:

The MP35N sheets are used in aerospace fasteners. They are also used in the medical and health care industries. The plates have great utilization in cryogenic equipment. They are very good in marine equipment because of its non eroding qualities. The sheets are used in aviation industries. The MP35N plates are also used in oil industries and gas industries. They are made of non toxic material they are used in food processing industries. The sheets are useful in constructions and bridges. The plates are included in applications of medical devices and dental products. They are also used in offshore equipment. They are also used in pressure housings.

Lint Steels continues to render good services recognizing our customers’ needs.

| Standard Specification : | ASTM F562 / ASME SF562 |

| Dimensions : | ASTM, ASME, and API |

| Sheets Thickness : | Range from .008″ to .0125″ |

| Plates Thickness : | Ranges from .0125″ to 5.00″ |

| Sheets/Plates Width : | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Sheets/Plates Length : | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Tempers : | Annealed, 1/4, 1/2 Hard, 3/4 Hard, Full Hard |

| Hardness : | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Value Added Service : | Cladding, Heat Treatment, Annealed, Pickling, Polish, Rolling, Cutting, Bending, Forging, Minor Fabrication Etc. |

ASTM F562 MP35N R30035 HR Sheet | MP35N Alloy Sheets Supplier in New Zealand| Nickel MP35N Sheet in South East Asia | MP35N® Alloy Sheets Stockist in Russia | Alloy R30035 Sheets Exporter in Europe | MP35N Perforated Sheets in South America | MP35N CR Sheet | Nickel Alloy MP35N Sheets | UNS R30035 Sheets Stockholder in Australia | Nickel MP35N Hot Rolled Sheets | MP35N® Alloy Shim Sheets | R30035 Sheets Importer| ASME SF562 MP35N Sheet | MP35N R30035 Sheets in Gulf

Nickel Alloy MP35N Plates | MP35N Alloy Plate in South East Asia | UNS R30035 Plates Stockholder in Australia | MP35N R30035 Plates Supplier in New Zealand| MP35N Plates Importer | ASTM F562 Nickel Alloy MP35N R30035 HR Plate | ASME SF562 MP35N Plate | MP35N R30035 Plates Stockist in Russia | MP35N CR Plate | MP35N R30035 Plates | MP35N® Hot Rolled Plates | MP35N R30035 Plates Exporter in Europe | Alloy R30035 Plates in Gulf | MP35N® Plate in South America

|

Chemical Analysis |

|

|

Cr |

20 nom |

|

Ni |

35 nom |

|

Mo |

10 nom |

|

Co |

35 nom |

| Material | Condtion | Ultimate Tensile Strength ksi | 0.2 % Yield Strength ksi | Elongation % | Reduction of Area % | Hardness HRC |

| MP35N AMS 5844 |

Solution Heat Treated and Work Strengthened | 255 | 225 | 12 | 50 | 45 |

| MP35N AMS 5845 |

Solution Heat Treated and Work Strengthened and Aged | 260 | 230 | 8 | 35 | 38 min |

There are many sectors and industries consuming MP35N Sheets / Plates like:

| Digesters and bleach plants in the paper industry | Sulfuric acid reactors |

| Components exposed to sour gas | Military |

| Oil and Gas industry | Defence & Aerospace Industries |

| Organic chloride process equipment | Evaporators, heat exchangers, filters and mixers used in sulfuric acid environments. |

| Equipment for flue-gas desulfurisation plants | Equipment for processes utilizing halide or acid catalysts |

France, Portugal, Austria, Spain, Morocco, Poland, Poland, Nigeria, Vietnam, Malaysia, Egypt, South Korea, Croatia, Israel, Chile, Ghana, Algeria, Angola, Trinidad & Tobago, Lebanon, United States, Mexico, Greece, Norway, Canada, Hungary, Sri Lanka, Bangladesh, India, Costa Rica, Bahrain, Macau, South Africa, Gambia, Indonesia, Belgium, Colombia, Nigeria, Singapore, Azerbaijan, Yemen, Switzerland, Australia, Brazil, Iraq, Netherlands, Oman, Tibet, Qatar, Ukraine, Bhutan, Belarus, Venezuela, Hong Kong, Pakistan, Sweden, Peru, Finland, Serbia, Estonia, Philippines, Saudi Arabia, Tunisia, Bulgaria, Argentina, Ecuador, Lithuania, Germany, Russia, Namibia, Kenya, New Zealand, Turkey, Kazakhstan, United Arab Emirates, Puerto Rico, Libya, Slovakia, Mongolia, Japan, Jordan, Taiwan, Gabon, Nepal, Zimbabwe, Czech Republic, Chile, Kuwait, Afghanistan, Denmark, United Kingdom, Mexico, China, Thailand, Bolivia, Romania, Ireland, Italy.

| Dubai | Abu Dhabi | Sharjah | Ajman | Al Ain | Ajman |

| Fujairah | Umm al-Quwain | Cairo | Manama | Istanbul | Baghdad |

| Riyadh | Ankara | Alexandria | Jeddah | Jeddah | Damascus |

| Basra | New Cairo | Doha | Kuwait City | Beirut | Sana’a |

| Yas Island | Muscat | Erbil | Aleppo | Marrakesh | Sharjah |

| Moscow | London | Saint Petersburg | Berlin | Madrid | Kyiv |

| Rome | Bucharest | Paris | Minsk | Vienna | Hamburg |

| Warsaw | Budapest | Barcelona | Munich | Kharkiv | Milan |

| Belgrade | Prague | Nizhny Novgorod | Kazan | Sofia | Birmingham |

| Brussels | Samara | Ufa | Rostov-on-Don | Cologne | Voronezh |

| Perm | Volgograd | Odessa | Sydney | Melbourne | Brisbane |

| Perth | Adelaide | Canberra | Hobart | Darwin | Gold Coast |

| Auckland | Christchurch | Wellington | Hamilton | Tauranga | Dunedin |

| Sao Paulo | Lima | Bogota | Rio de Janeiro | Santiago | Caracas |

[popup_anything id=”2305″]

Head Office - Prasad chambers 912, 9th floor, Near Charni road station, Tata Road no. 2, Mumbai -400004.

Back Office - 32/34, Damodar Niwas, Second Floor, C. P. Tank, Mumbai 400004.